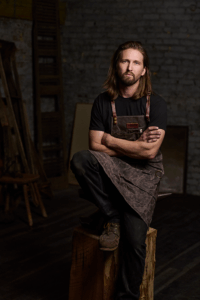

About Matt Olseng, Co-owner

At the Right Hand of the Father

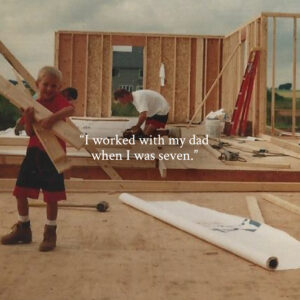

I began my journey with tools in hand and awe in my eyes. At the age of seven, my father, a home builder, woke me early one morning and said, “You’re coming to work with me today.” To a young boy, that was nothing short of a summons to adventure. My father was my hero, and I eagerly leapt out of bed with a simple, “Okay!”

This particular project was special—it was the first home my father was building for his own family. From foundation to roof, I watched in wonder as he shaped our future home with skill, precision, and a quiet, commanding presence. I spent the day by his side, probably more a hindrance than a help, but desperate to contribute. I swept floors, picked up nails one by one, and carried a tiny toolbelt holding an old hammer, a pencil, and a collection of bent nails I had rescued from the ground.

At one point my father asked me to carry a bunch of 2×4’s from one place to another. I began carrying them one at a time when my father said something I have never forgotten: “You can carry more than that, can’t you?” I nodded, and he replied, “You make sure you always carry as much as you can. Work isn’t easy, but when we work, we work hard.”

Those words broadened my little shoulders that day and planted the seed of a work ethic I have carried ever since, and shaped the way I approach every challenge in life and in craft.

Low Points Spark a New Interest

As a kid, motorcycles fascinated me. I lived for the competition, the speed, and the skill it demanded. Mistakes are punished racing motorcycles. In June 2002, on the weekend of my sixteenth birthday, that passion nearly ended when a mistake resulted in a shattered pelvis, leaving me unable to walk for months.

Stuck at home, unable to move around without crutches and reliant on my parents for even the simplest tasks, I searched for a new outlet. Television shows about metal fabrication and custom motorcycles caught my eye—builders welding, shaping, and creating. Watching them, I realized that I could channel my energy into a new skill: welding.

I bought a cheap welder from Home Depot and set it up in the garage. From the moment I started, I was hooked. Welding gave me a way to make things permanent, to transform raw steel into objects of utility and beauty. That summer, seated in a chair, I welded everything I could find. A new passion was born, one that would define the trajectory of my life.

My First Job

After a summer spent welding in the garage, I was ready to turn passion into practice. The school offered internships, and I decided to set up my own. I found a two-man fabrication shop, called the owner, and explained that I didn’t need pay—I simply wanted experience.

Two weeks before school started, fate intervened. The shop’s only employee quit, and the owner offered me a real job. That was my first “interview,” though no words were exchanged beyond a simple, “Do you want the job?” My answer was immediate: yes.

Diverse Work Breeds Versatility

At that shop, no day was ever the same. I worked on heavy equipment, repaired machinery, fabricated parts for M1 Abrams tanks, prototyped rescue systems for the fire service, built steel structures and railings, and even welded a rocket launcher for safe demonstration. I fixed every type of broken office chair imaginable.

That shop taught me adaptability, problem-solving, and the courage to tackle the unknown. We pivoted from project to project daily, never knowing what the next challenge would be—but always confident that with focus and effort, we could figure it out. This versatility became the foundation of my craftsmanship and entrepreneurial journey.

The Big Leap

One day, an architect my father knew asked me to make a polished stainless steel pot rack. Though I had never made something quite like it, I accepted the challenge. The piece took time and experimentation, but the client loved it. That single commission opened doors. Suddenly, people saw what I could create beyond repairs and industrial fabrication—they saw artistry, precision, and vision.

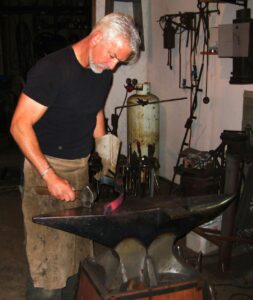

A Blacksmith Without an Anvil

I improvised: a thick steel plate became my anvil, a ball pein hammer my tool, and a torch my forge. Hours of trial and error followed, learning how to shape flowing scrolls and fishtail ends, coaxing motion and fluidity from the metal. In the end, the client was thrilled, and I had discovered blacksmithing—a skill that would define my career.

The Flood

After that first forging project, opportunities multiplied. Word of my work spread through builders, designers, and architects. I joined NOMMA (National Ornamental & Miscellaneous Metals Association), entering design competitions that judged craftsmanship nationwide. It was also in this organization that I met Kara.

My first entry—that French canopy—won a silver medal, igniting that competitive fire within me. Just as racing once did. Over the next five years, my shop won 13 awards, culminating in the Mitch Heitler Award for Excellence for a forged copper-nickel railing. That project, unusual in material and form, exemplified my signature style: modern work that looks like an heirloom on day one.

Through it all, the pattern remained: I often accepted projects with no prior knowledge, relying on problem-solving, determination, and a willingness to learn.

Ironware Calls

In the spring of 2020, I had just purchased a building and added sophisticated machinery to my operation—preparing to scale up when the pandemic struck. Amid uncertainty, in 2021, I received an email from Karin Eaton, owner of Ironware International, a luxury lighting company in Nashville. COVID significantly disrupted the trading relationship with their French manufacturer. As a result, she was seeking a U.S.-based blacksmith capable of executing the full range of their products.

Through mutual NOMMA connections, I was referred to Karin, as someone that would take on her project and help solve her dilemma. I met Karin in person in southern Indiana while working on a structure installation with Kara. We saw the beauty and skill of her pieces firsthand, and an agreement was reached: MDO would manufacture Ironware’s products domestically.

Evolution in Process

For the next two years, we learned to reproduce Ironware’s entire product line with no drawings or tooling from the French manufacturer. Using photographs, skill, and experience, we rebuilt processes from scratch. Mistakes were inevitable, but through trial and careful refinement, we developed a system that preserved the handmade quality while improving efficiency and repeatability.

The process was laborious, demanding, and intensely satisfying. Every day, we reinforced our philosophy: honoring traditional craftsmanship while embracing innovation where it serves the work, never at the cost of the handmade soul of the pieces.

The Opportunity Arises

After two years of successful collaboration, Karin was ready to retire and sell Ironware after 36 years at the helm. Kara and I faced a life-changing opportunity: to own a company dedicated to handcrafted furniture and lighting—our shared dream realized.

Though the company was in another state, and our lives were already full, every step of our past had prepared us. My father’s lesson to “carry as much as you can” echoed through every decision, reminding us that hard work, perseverance, and courage could turn possibility into reality.

In September 2023, we purchased Ironware. Since then, we have poured our energy, vision, and passion into shaping the company into a reflection of our craft, values, and dedication to making work that combines beauty, utility, and soul.

The Future

Our vision for Ironware is simple yet profound: to honor the timeless craft of blacksmithing while creating pieces that are meaningful, functional, and heirloom-worthy from day one. We continue to refine processes, embrace challenges, and mentor the next generation of artisans.

Ironware is more than a company; it is a platform to celebrate creativity, skill, and passion. Every forged scroll, every polished surface, and every meticulously crafted piece tells a story—our story, intertwined with the legacy of those who taught us, inspired us, and trusted us to carry their vision forward.

We work hard, carry all we can, and strive to create functional art that will endure, inspire, and captivate for generations to come.

One backed by nearly 40 years of proven craftsmanship and a team whose collective expertise spans generations. One that your grandkids will fight over inheriting. One that makes guests stop mid-conversation to ask, “Where did you get that?” One that represents the same devil-may-care creativity and uncompromising quality that’s been passed down through generations of makers who refused to play it safe.

One backed by nearly 40 years of proven craftsmanship and a team whose collective expertise spans generations. One that your grandkids will fight over inheriting. One that makes guests stop mid-conversation to ask, “Where did you get that?” One that represents the same devil-may-care creativity and uncompromising quality that’s been passed down through generations of makers who refused to play it safe.